H-Pile Walls

H-pile walls use driven or drilled steel H-beams with lagging between flanges to create robust earth retention systems for deep excavations, bridge abutments, and permanent retaining structures.

Understanding H-Pile Walls

H-pile walls—also called soldier pile walls when used with lagging—are one of the most versatile and proven earth retention systems in geotechnical construction. Steel H-shaped beams are driven or drilled into the ground at regular spacing, then horizontal lagging (timber, concrete, or shotcrete) is installed between the pile flanges as excavation proceeds.

For taller walls or higher loads, tieback anchors or internal bracing add lateral support. H-pile walls excel in urban environments where speed, flexibility, and the ability to work around utilities matter. They can be designed as temporary shoring or permanent retaining structures with design lives exceeding 75 years.

This technique is used in our services for:

Typical Applications

How It Works

Our proven methodology ensures consistent, high-quality results for every installation.

Survey and Layout

Survey pile locations and mark utilities. Verify property lines and coordinate with adjacent property owners. Establish pile spacing based on wall design and soil conditions.

Pre-Drilling (If Required)

In dense soils, rock, or where vibration must be minimized, pre-drill pilot holes to design depth. Pre-drilling also helps navigate around utilities and obstructions.

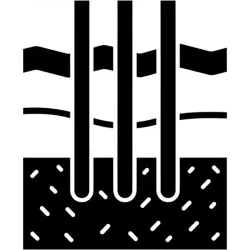

Pile Installation

Drive or vibrate H-piles to design depth and embedment. Verify pile alignment and elevation. For drilled installations, set pile in hole and grout or backfill around pile.

Excavation in Lifts

Excavate soil in controlled lifts (typically 4-5 feet) between pile rows. Maintain stable excavation face and install lagging promptly after each lift.

Lagging Installation

Install timber, precast concrete, or shotcrete lagging between pile flanges. Lagging transfers soil pressure to piles. Pack voids behind lagging with pea gravel or lean concrete.

Tieback or Bracing Installation

At design elevations, install and stress tieback anchors or internal bracing to resist lateral earth pressure. Continue excavation and lagging below anchor level.

Wall Completion

Complete excavation to final grade. Install final lagging, drainage systems, and any architectural facing. For permanent walls, apply protective coatings or concrete facing.

Key Advantages

Urban Construction Expertise

H-pile walls are ideal for city construction where adjacent buildings, utilities, and property lines create constraints. The discrete pile spacing allows work around obstacles.

Depth Versatility

From 15-foot basement walls to 100+ foot deep excavations, H-pile walls scale by adding tieback levels or increasing pile size. The same basic system handles a wide range of depths.

Speed of Construction

Pile driving is fast, and lagging installs as excavation proceeds. Well-coordinated crews can install significant wall lengths quickly, keeping construction schedules on track.

Lagging Options

Timber lagging is economical and fast for temporary walls. Concrete lagging or shotcrete provides durability for permanent structures. Lagging choice matches project requirements and budget.

Tieback Compatibility

H-pile walls work seamlessly with tieback anchor systems. Waler beams attached to pile flanges distribute anchor loads evenly, creating efficient high-capacity walls.

Technical Considerations

Soil/Rock Conditions

H-piles drive well in most soils. Cobbles, boulders, or shallow rock may require pre-drilling. Pile embedment below excavation must be sufficient to develop passive resistance or must be supplemented with tiebacks.

Groundwater

H-pile walls are not inherently watertight. In high groundwater conditions, combine with dewatering, grouting, or sheet pile cutoff. Drainage behind lagging is essential to prevent hydrostatic pressure buildup.

Load Capacity

Wall capacity depends on pile size, spacing, embedment, and tieback/bracing. Structural analysis considers active and passive earth pressures, surcharge loads, and water pressure if present.

Spacing

Closer pile spacing increases wall stiffness and reduces lagging span. Typical 6-8 ft spacing balances cost and performance. Tighter spacing for softer soils or higher walls.

Installation Method

Driven piles are fastest but create vibration. Drilled and grouted piles minimize vibration for sensitive adjacent structures. Vibratory driving is intermediate option.

Equipment Used

- Pile driving rigs (impact or vibratory)

- Drill rigs for pre-drilling

- Cranes for pile handling

- Excavators

- Tieback drilling and stressing equipment

- Shotcrete equipment (if shotcrete lagging)

Limitations

- Not watertight without additional measures

- Driven piles create noise and vibration

- Requires adequate embedment zone below excavation

- Utility conflicts may require design modifications

- Timber lagging has limited fire resistance

Technical Specifications

System Variations

Cantilevered H-Pile Wall

For walls up to 15-20 feet, pile embedment alone provides stability without tiebacks or bracing. Simple, economical, but limited to lower wall heights.

Best For:

- Shallow excavations

- Temporary construction access

- Low-surcharge conditions

Single-Tier Anchored Wall

One level of tieback anchors supports walls up to 25-35 feet. Anchors installed after partial excavation, stressed, then excavation continues to final grade.

Best For:

- Mid-depth basements

- Parking structures

- Moderate excavation depths

Multi-Tier Anchored Wall

Multiple rows of tiebacks support deep excavations. Each anchor level is installed and stressed before excavating to the next level.

Best For:

- Deep basements

- Underground parking

- Subway stations

Internally Braced Wall

Instead of tiebacks, internal struts or rakers brace the wall against the opposite wall or excavation floor. Used where tiebacks would conflict with adjacent properties.

Best For:

- Property line excavations

- Areas with tieback easement issues

- Wide excavations with cross-bracing

Integration With Other Systems

Tieback Anchors

Tieback anchors provide lateral support for H-pile walls. Waler beams connect anchors to pile flanges, distributing loads across the wall system.

Learn More

Steel Lagging

Steel plates or shotcrete provide lagging options. Steel is fast for temporary walls; shotcrete creates durable permanent facing.

Learn More

Micropiles

Micropiles underpin adjacent structures before H-pile wall installation, protecting existing foundations during excavation.

Learn More

Pressure Grouting

Grouting can stabilize loose soils behind lagging, fill voids, or improve pile-soil bond in drilled installations.

Learn MoreExample Project Types

- High-rise building foundations

- Basement construction

- Underground parking structures

- Bridge abutments and wing walls

- Highway widening and underpasses

- Transit station excavations

- Industrial facility foundations

- Waterfront development

Why Choose Rock Supremacy for H-Pile Walls

Urban Experience

Our crews understand the challenges of urban construction—working around utilities, managing vibration near adjacent buildings, and coordinating with tight site logistics.

Design-Build Capability

We design and build H-pile walls, providing single-source responsibility from engineering through installation. One team, clear accountability.

Tieback Integration

Our tieback anchor crews work seamlessly with pile installation. We handle the complete wall system, not just components.

Multiple Lagging Options

We install timber, concrete, and shotcrete lagging. Shotcrete capability enables architectural finishes for permanent exposed walls.

Schedule Performance

Experienced crews and well-maintained equipment mean reliable production rates. We deliver H-pile walls on schedule to keep your project moving.

Our Work

See how we've applied this technique and others to solve real-world geotechnical challenges.

I-70 Corridor Stabilization

Installed 50,000 sq ft of high-tensile mesh and performed extensive scaling after a major weather event.

Lava Hot Springs Slope Stabilization

Multi-phase slope stabilization project protecting the historic hot springs resort and Highway 30 from an active landslide.

Moffat Subdivision Railroad Stabilization

Large-scale railroad stabilization project with over 10,000 linear feet of drilling to secure train tracks entering the historic Moffat Tunnel.

H-Pile Walls FAQ

Client Testimonials

Trusted by DOTs, engineering firms, and property owners nationwide.

Deploy Us

Ready to discuss your project? Our team is standing by to assess your site conditions and develop a custom solution using H-Pile Walls and other proven techniques.

Emergency (24/7)

(541) 383-7625Bidding & Estimates

Info@RockSupremacy.comHeadquarters

Licensed in CO, UT, WY, ID, MT, CA, WA, OR, TN, VA

Request Consultation

Related Techniques

Explore other engineering methods we use to deliver comprehensive geotechnical solutions.

Micropiles

Micropiles are small-diameter, high-strength deep foundation elements used to transfer loads into competent ground. Their versatility makes them ideal for underpinning, slope stabilization, and situations with limited access or difficult geology.

Secant Pile Walls

Secant pile walls are interlocking drilled concrete piles that create continuous structural walls with groundwater cutoff capability for deep excavations in saturated soils and urban environments.

Soldier Pile Walls

Soldier pile walls are proven earth retention systems for stabilizing deep excavations and steep slopes. Steel beams installed at intervals with lagging placed between them provide flexible, economical support that adapts to site constraints.

Steel Plate & Shotcrete Lagging

Lagging systems span between soldier piles using steel plates, timber, or shotcrete to retain soil during excavation. The choice of lagging material affects installation speed, cost, permanence, and aesthetic finish.