Tieback Anchors

Tieback anchors provide active lateral reinforcement for retaining walls, excavation support systems, and slope stabilization by transferring loads deep into stable ground or rock. These post-tensioned elements are essential for deep excavations and high-load applications.

Understanding Tieback Anchors

Tieback anchors provide active lateral reinforcement for retaining walls, excavation support systems, and slope stabilization by transferring loads deep into stable ground or rock. These post-tensioned elements are essential for deep excavations and high-load applications.

By pre-stressing anchors to design load before construction proceeds, tiebacks actively resist lateral forces rather than waiting for movement to develop resistance.

This technique is used in our services for:

Typical Applications

How It Works

Our proven methodology ensures consistent, high-quality results for every installation.

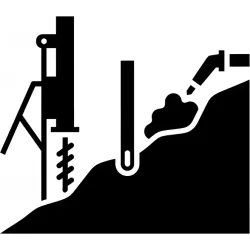

Drilling

Drill through wall or slope face into stable bearing zone at designed angle and depth.

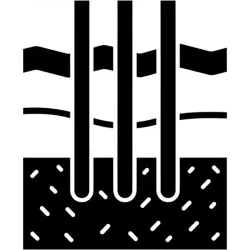

Tendon Installation

Insert strand bundle or threadbar with centralizers and corrosion protection.

Grouting

Pressure grout the bond zone to develop anchor capacity in surrounding ground.

Stressing & Lock-Off

Tension anchor to design load, verify performance, and lock off at bearing plate.

Key Advantages

Active Load Resistance

Unlike passive systems, tiebacks are pre-stressed to design load, immediately resisting lateral forces without requiring wall movement.

High Capacity

Multi-strand anchors develop capacities exceeding 500 kips, supporting deep excavations and heavy structures.

Proof Testing

Every anchor is tested to verify capacity before lock-off, ensuring reliable performance.

Design Flexibility

Anchors can be installed at various angles and lengths to optimize load transfer into available bearing material.

Long Service Life

Double corrosion protection systems provide 75+ year service life for permanent installations.

Technical Considerations

Soil/Rock Conditions

Bond zone must be in competent material. Rock provides highest capacity; soil anchors require longer bond lengths. Casing may be needed in caving ground.

Groundwater

Grouting methods adapted for wet conditions. Corrosion protection essential in aggressive groundwater environments.

Load Capacity

Capacity depends on tendon size, grout strength, and bond length in bearing material. All anchors proof-tested to 133% of design load.

Spacing

Anchor spacing determined by wall design and allowable loads. Typical spacing 6-10 ft horizontal, one or more rows vertically.

Installation Method

Rotary or percussion drilling at design angle. Tendon placed with centralizers, grouted under pressure, stressed after grout cure.

Equipment Used

- Track or crane-mounted drill rigs

- Hollow-stem augers or casing systems

- Grout mixing and pumping equipment

- Multi-strand stressing jacks

- Load cells and pressure gauges

Limitations

- Requires access beyond property line or easements

- Bond zone must be in stable material

- Corrosion protection critical for permanent anchors

- Creep testing required for some soil conditions

Technical Specifications

System Variations

Strand Anchors

Multiple high-strength strands provide maximum capacity for heavy-load applications.

Best For:

- Deep excavations

- High retaining walls

- Dam anchoring

Threadbar Anchors

Single high-strength threadbar for moderate loads with simple installation and restressability.

Best For:

- Moderate loads

- Temporary shoring

- Slope stabilization

Removable Anchors

Anchors designed for extraction after temporary use, avoiding permanent encroachment.

Best For:

- Temporary excavation support

- Property line constraints

- Urban construction

Double Corrosion Protected

Encapsulated tendons with grouted corrugated sheath for permanent installations.

Best For:

- Permanent walls

- Critical infrastructure

- Aggressive environments

Integration With Other Systems

Soldier Pile Walls

Tiebacks provide lateral support for soldier piles, allowing deep excavations with minimal wall movement.

Learn More

Micropiles

Micropiles provide vertical support while tiebacks resist lateral earth pressure.

Learn More

Shotcrete Facing

Shotcrete facing distributes tieback loads across the wall face and provides erosion protection.

Learn More

Soil Nailing

Combination systems use tiebacks for high loads with soil nails for distributed reinforcement.

Learn MoreExample Project Types

- Deep basement excavations

- Highway cut slope retention

- Bridge abutment support

- Dam and spillway anchoring

- Existing wall remediation

- Landslide stabilization

- Waterfront structures

Why Choose Rock Supremacy for Tieback Anchors

PTI-Certified Crews

Our installers are trained and certified in post-tensioning procedures for reliable anchor performance.

Full Testing Capability

In-house stressing equipment and experienced technicians ensure proper proof testing of every anchor.

Difficult Access Expertise

Track-mounted and limited-access rigs allow tieback installation in constrained urban and mountainous sites.

Quality Documentation

Complete installation records including drilling logs, grout takes, and test results for owner files.

Integrated Solutions

We combine tiebacks with soldier piles, shotcrete, and drainage for complete excavation support systems.

Our Work

See how we've applied this technique and others to solve real-world geotechnical challenges.

I-70 Corridor Stabilization

Installed 50,000 sq ft of high-tensile mesh and performed extensive scaling after a major weather event.

Lava Hot Springs Slope Stabilization

Multi-phase slope stabilization project protecting the historic hot springs resort and Highway 30 from an active landslide.

Moffat Subdivision Railroad Stabilization

Large-scale railroad stabilization project with over 10,000 linear feet of drilling to secure train tracks entering the historic Moffat Tunnel.

Tieback Anchors FAQ

Client Testimonials

Trusted by DOTs, engineering firms, and property owners nationwide.

Deploy Us

Ready to discuss your project? Our team is standing by to assess your site conditions and develop a custom solution using Tieback Anchors and other proven techniques.

Emergency (24/7)

(541) 383-7625Bidding & Estimates

Info@RockSupremacy.comHeadquarters

Licensed in CO, UT, WY, ID, MT, CA, WA, OR, TN, VA

Request Consultation

Related Techniques

Explore other engineering methods we use to deliver comprehensive geotechnical solutions.

Micropiles

Micropiles are small-diameter, high-strength deep foundation elements used to transfer loads into competent ground. Their versatility makes them ideal for underpinning, slope stabilization, and situations with limited access or difficult geology.

Rock Bolting

Rock bolting stabilizes fractured, jointed, or unstable rock masses by anchoring steel bars deep into competent rock. By tying loose blocks back to stable substrate, rock bolts improve the overall strength and cohesion of slopes, cuts, tunnels, and vertical faces.

Soil Nailing

Steel bars driven into soil to reinforce and stabilize loose ground or slope faces.

Soldier Pile Walls

Soldier pile walls are proven earth retention systems for stabilizing deep excavations and steep slopes. Steel beams installed at intervals with lagging placed between them provide flexible, economical support that adapts to site constraints.